Hot Melt Adhesive Film

Hot Melt Adhesive Film Specification

- Type

- Hot Melt Adhesive Film

- Material

- EVA (Ethylene Vinyl Acetate)

- Tensile Strength

- > 2 MPa

- Working Temperature

- 90C 150C

- Density

- 0.93 Gram per cubic centimeter(g/cm3)

- Length

- 100 m per roll

- Width

- 10 cm 150 cm

- Thickness

- 0.05 mm to 0.20 mm

- Transparency

- Semi-transparent

- Hardness

- Medium

- Size

- Custom sizes available

- Color

- Clear

- Packaging

- Roll, packed in moisture-proof wrapping

- Surface Finish

- Glossy

- Melting Point

- 80C 120C

- Peel Strength

- > 1.5 N/cm

- Adhesive Type

- Solid film, pressure-sensitive

- Application Method

- Heat press or lamination

- Storage Conditions

- Store in a cool and dry place

- Usage

- Textile, automotive, electronics, footwear bonding

- Odor

- Odorless

- Bonding Time

- 815 seconds

- Shelf Life

- 24 months

About Hot Melt Adhesive Film

Feature

High Adhesion Strength: Hot melt TPU films provide strong bonding capabilities to a variety of materials, including fabrics, plastics, metals, and more; Flexibility at Low Temperatures: These films maintain good flexibility even at low temperatures, ensuring performance in a range of environmental conditions; High Extensibility: Hot melt TPU films exhibit high extensibility, allowing them to stretch significantly without losing their structural integrity; Fast Crystallization Rate: They have a rapid crystallization rate, which helps in achieving strong and durable bonds quickly during the application process

Application

Textile Lamination: Used to bond layers of fabric, providing durability and flexibility in products like sportswear, outdoor clothing, and technical textiles. ; Footwear: Applied in the production of shoe components, such as uppers and insoles, to enhance adhesion and performance.Automotive: Used in the interior components of vehicles, such as seating and trim, for their strong bonding capabilities and flexibility.

High Performance and Versatile Bonding

This hot melt adhesive film delivers robust bonding for diverse applications such as textiles, automotive interiors, electronics assembly, and footwear manufacturing. Its medium hardness and tensile strength (>2 MPa) ensure consistent adhesion and durability, while the semi-transparent finish enhances visual appeal and subtlety on bonded materials.

User-Friendly Application and Storage

The adhesive film is simple to apply using heat press or lamination at working temperatures between 90C and 150C. Its solid, pressure-sensitive form ensures minimal mess and reliable results. Store in a cool, dry place and enjoy an impressive 24-month shelf life with each roll safely packed to prevent moisture damage during shipment and storage.

FAQ's of Hot Melt Adhesive Film:

Q: How should I apply the Hot Melt Adhesive Film for optimal results?

A: For the best bond, place the adhesive film between the materials to be joined and use a heat press or laminator set between 90C and 150C. Apply pressure for 8-15 seconds to activate adhesion, ensuring a strong and durable joint.Q: What materials and industries is this adhesive film suitable for?

A: This film is ideal for bonding in the textile, automotive, electronics, and footwear sectors. Its versatility accommodates various surfaces and materials, providing secure adhesion in demanding environments.Q: When does the adhesive film reach peak bonding strength after application?

A: During heat press or lamination, the adhesive film achieves full bonding strength within 8-15 seconds at the recommended working temperatures.Q: Where should I store the adhesive film to maintain its effectiveness?

A: Store the rolls in a cool, dry area, away from direct sunlight and moisture. Proper storage is essential to preserve the adhesive's integrity throughout its 24-month shelf life.Q: What are the benefits of using a semi-transparent, pressure-sensitive hot melt adhesive film?

A: The semi-transparent property allows subtle, neat bonding, while its pressure-sensitive nature ensures easy handling with minimal waste. The glossy, odorless finish adds to product quality and user comfort.Q: Is the adhesive film available in custom sizes or widths for different applications?

A: Yes, the film is offered in a variety of thicknesses (0.05 mm-0.20 mm), widths (10 cm-150 cm), and custom sizes, accommodating diverse application needs and manufacturing setups.

- Minimum Order Quantity

- 100 Units

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in TPU Hot Melt Films Category

Two Layer Composite Waterproof Film

Minimum Order Quantity : 100 Units

Material : PE + EVA

Type : Other, Composite Waterproof Film

Width : 12 m

Hardness : Soft

Color : White

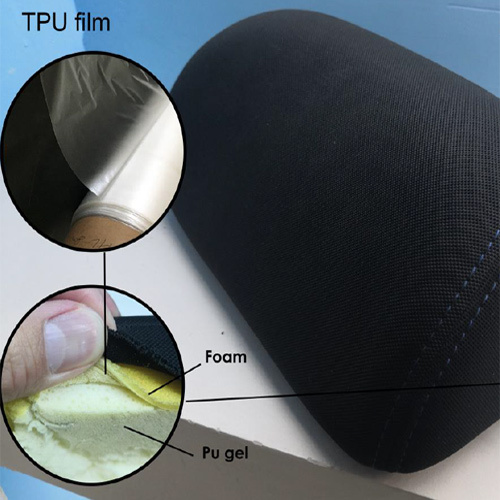

PU Foam Surface Film

Minimum Order Quantity : 100 Units

Material : PU Foam

Type : Other, Surface Film

Width : Up to 1.5 meters

Hardness : Soft

Color : Grey

Send Inquiry

Send Inquiry Send SMS

Send SMS