Labelling Film

Labelling Film Specification

- Type

- Labelling Film

- Material

- BOPP

- Tensile Strength

- Excellent

- Working Temperature

- -10C to 50C

- Density

- 0.93 Gram per cubic centimeter(g/cm3)

- Length

- 1000 4000 m

- Width

- 200 mm to 1600 mm

- Thickness

- 12-50 micron

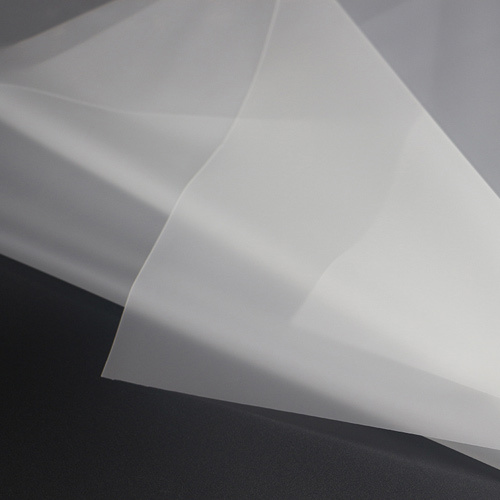

- Transparency

- Highly Transparent

- Hardness

- Medium

- Size

- Customisable

- Color

- Clear

- Surface Treatment

- Corona Treated

- Printing Compatibility

- Flexo, Gravure, Offset

- Shrinkage

- <5%

- Moisture Resistance

- High

- Surface Finish

- Smooth

- Gloss Level

- High Gloss

- Recyclability

- 100% Recyclable

- Heat Sealability

- Yes

- Application

- Self-adhesive labels, Shrink labels, Wrap-around labels

- Packaging Type

- Rolls

- Minimum Order Quantity

- 500 Kg

About Labelling Film

Feature:

TPU (Thermoplastic Polyurethane) films are a popular choice for labels and badges in the shoes and fashion industry due to their unique combination of properties. Here are some key features and benefits:

- Durability: TPU films are highly resistant to wear and tear, ensuring that labels and badges remain intact and legible throughout the lifespan of the product. This is particularly important for footwear, which undergoes significant stress and abrasion.

- Flexibility: These films offer excellent flexibility, allowing labels and badges to conform to the curves and movements of shoes and garments without cracking or peeling. This ensures a seamless and comfortable fit.

- Aesthetic Appeal: TPU films can be customized with various colors, finishes (such as matte or glossy), and designs. This versatility allows fashion brands to create visually appealing labels and badges that enhance the overall look of their products.

- Water and Chemical Resistance: TPU films are resistant to water, oils, and many chemicals, making them ideal for use in environments where footwear and garments might be exposed to these elements. This ensures that the labels and badges remain unaffected and maintain their quality.

- Adhesion: TPU films adhere well to various substrates, including synthetic and natural fabrics, leather, and plastics. This strong adhesion ensures that labels and badges stay securely attached, even under strenuous conditions.

- Eco-Friendly Options: With growing emphasis on sustainability, many TPU films are now available in eco-friendly options, made from biodegradable or recyclable materials. This aligns with the fashion industry's increasing focus on sustainability. By incorporating TPU films, brands can ensure their labels and badges not only meet high standards of durability and functionality but also contribute to the aesthetic and sustainable values of their products.

Application

Sports Shoes, Garments, Outerwear

Exceptional Moisture Resistance for Reliable Performance

Our BOPP labelling film maintains label integrity even in humid and challenging environments due to its high moisture resistance. This makes it suitable for packaging applications where moisture can affect adhesion or print quality, ensuring labels remain legible and intact throughout the product's lifecycle.

Versatile Application Compatibility

Ideally designed for self-adhesive, shrink, and wrap-around label formats, this film suits a wide variety of product segments. Its smooth surface finish and high gloss not only enhance visual appeal but also boost the efficiency of labeling machines, optimizing operational productivity.

Eco-Friendly and Adaptable Value

With 100% recyclability and customizable dimensions, this labelling film supports sustainable packaging initiatives and adapts seamlessly to unique branding needs. Supplied in rolls and compatible with major printing techniques, it meets diverse requirements while reducing environmental impact.

FAQ's of Labelling Film:

Q: How does the corona surface treatment enhance printing and adhesion on the labelling film?

A: The corona treatment increases the film's surface energy, improving ink adhesion during printing and enhancing self-adhesive properties for labels. This results in vibrant, durable prints and reliable label performance.Q: What label applications can this BOPP film be used for?

A: This film is suitable for self-adhesive labels, shrink labels, and wrap-around labels. Its high gloss and transparency ensure professional presentation on a wide range of products.Q: What is the process for ordering custom-sized labelling films, and what is the minimum order quantity?

A: To order customised sizes, you can specify required length (1000-4000 m) and width (200-1600 mm) within your inquiry. The minimum order quantity is 500 kg per specification.Q: Where is this labelling film manufactured and supplied?

A: This labelling film is made and distributed by manufacturers, exporters, suppliers, traders, and wholesalers across India, ensuring timely and efficient delivery nationwide.Q: When can this film be used in the packaging process, considering working temperature and heat sealability?

A: The film can be integrated into packaging lines that operate within -10C to 50C, and its heat sealability makes it ideal for both manual and automated packaging applications, promoting processing efficiency.Q: What benefits does high moisture resistance and high gloss provide for label performance?

A: High moisture resistance prevents label degradation in damp settings, while high gloss enhances product visibility, brand recognition, and shelf appeal-making products stand out to customers.Q: Is the labelling film environmentally friendly and recyclable after use?

A: Yes, the film is 100% recyclable, supporting eco-friendly packaging goals and helping companies reduce waste and environmental footprint.

- Minimum Order Quantity

- 30 Meter

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in TPU Films Category

Antistatic Clear TPU Film

Color : Clear

Thickness : 0.1 mm to 0.5 mm

Size : Customizable

Hardness : Other, 85A to 95A

Material : TPU (Thermoplastic Polyurethane)

Polyester TPU Film

Minimum Order Quantity : 100

Color : On request

Thickness : 0.02 to 1 Millimeter (mm)

Size : 54 Inch, 62 Inch & others on special request

Hardness : Soft

Material : Polyester TPU

Polyether TPU Film

Minimum Order Quantity : 100

Color : On request

Thickness : 0.02 to 1 Millimeter (mm)

Size : 54 Inch, 62 Inch & others on special request

Hardness : Soft

Monolithic High Breathable Membranes

Minimum Order Quantity : 10 Pieces

Color : Translucent, White & Clear

Thickness : 0.02 to 0.05 Millimeter (mm)

Send Inquiry

Send Inquiry Send SMS

Send SMS